Understanding the nuances of freight calculation is essential for businesses involved in shipping and logistics. Freight calculation involves determining the cost associated with transporting goods from one location to another. Precision in this calculation is crucial as it affects both cost management and client satisfaction.

Freight costs are influenced by several factors including weight, dimensions, distance, and mode of transportation. Among these, accurate weight measurement stands out as a significant determinant. Incorrect weight calculations can lead to either undercharging or overcharging, causing financial discrepancies and affecting supply chain efficiency.

The Role of Weighing Paper in Freight Calculation

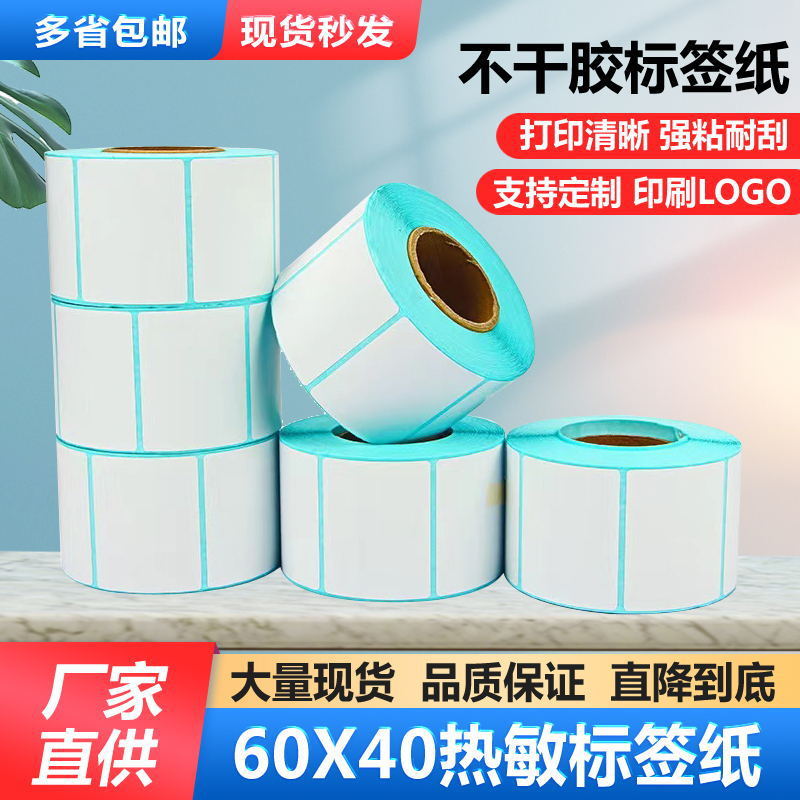

Weighing paper plays an instrumental role in achieving precise weight measurements. Essentially, it is a specialized type of paper used during the weighing process to enhance accuracy. Unlike traditional methods such as using standard scales or estimating weights, weighing paper provides a more refined approach by ensuring that all packaging materials are accounted for correctly.

Using weighing paper minimizes human error and inconsistencies often found in other methods of weight measurement. This precision helps prevent disputes related to shipping charges and ensures fairness in pricing. In comparison to manual measuring and estimation techniques, weighing paper emerges superior due to its ability to offer detailed and reliable results consistently.

Benefits of Using Weighing Paper

One of the primary benefits of incorporating weighing paper into your freight calculation process is enhanced accuracy. It eliminates guesswork and aligns actual weights with recorded ones, thereby avoiding potential miscalculations.

This heightened accuracy significantly reduces shipping errors and disputes between shippers and carriers. By providing clear-cut evidence of weight, any disagreements regarding charges can be quickly resolved.

Cost-saving is another considerable advantage. With exact weight measurements, you can avoid overpayment on freight charges and optimize your shipping expenses effectively.

Types of Weighing Paper and Their Applications

There are various types of weighing papers designed for different applications. For instance, high absorbency weighing papers are ideal for weighing wet substances while anti-static versions are perfect for powders and fine particles. Understanding these differences will help you choose the right kind of weighing paper tailored to your specific needs.

Choosing the appropriate type of weighing paper hinges on understanding the nature of your shipments. For dry goods, a simple lightweight option might suffice; whereas, for delicate or fine items, you may need something more sophisticated like anti-static weighing paper.

Implementing Weighing Paper in Your Shipping Process

Incorporating weighing paper into your shipping routine begins with acquiring the necessary tools and equipment. High-quality weighing papers, reliable scales, and proper handling protocols form the cornerstone of efficient deployment.

A step-by-step guide includes placing the weighing paper on the scale before adding your package. Always ensure consistency by zeroing the scale prior to each use. Employ best practices such as regular calibration of weighing equipment and training personnel to handle weighing paper accurately.

Common Challenges and Solutions

Despite its advantages, there might be challenges when using weighing paper. Issues such as tearing or moisture absorption can distort readings. To overcome these, always store weighing papers in a controlled environment away from dampness or contaminants.

Real-world examples illustrate successful implementation despite obstacles. Consider a scenario where a company initially faced frequent shipment disputes. Upon integrating weighing paper, they noticed a substantial decline in disagreements and reported improved client relationships and reduced administrative overheads.

Case Studies: Success Stories

Company A's experience highlights a dramatic reduction in shipping costs after adopting weighing paper. They streamlined their freight calculation process and saw diminished billing adjustments and refunds.

On the other hand, Company B experienced a notable boost in shipping efficiency. The precise weight recordings expedited load planning and decreased delays, enhancing overall operational speed.

Lessons drawn emphasize the importance of meticulous application and consistent usage. Both companies underscore continuous improvement and adaptation based on real-time feedback and performance metrics.

Emerging technologies are set to complement the use of weighing paper further. Innovations such as digital scales integrated with data analytics software promise even greater accuracy and actionable insights. Predictions indicate a blend of traditional methodology with modern tech solutions guiding future freight calculations.

The role of weighing paper is expected to evolve amidst these technological advancements. As new algorithms and intelligent systems become mainstream, weighing paper remains fundamental in ensuring baseline accuracy and establishing trustworthiness in automated processes.

Advice from industry professionals emphasizes habitually calibrating your weighing instruments and maintaining stringent quality checks. Strategically train staff to understand and implement standardized procedures thoroughly.

Continual improvement requires staying updated with the latest trends and technologies. Utilize resources like industry publications, workshops, and professional development courses. Engaging with a network of experts also facilitates knowledge sharing and practical problem-solving strategies.