Importance of Efficient Dispatch Operations

Efficient dispatch operations are a cornerstone for any business involved in the shipping and delivery of goods. The impact on customer satisfaction cannot be overstated—delays or errors can lead to negative reviews, decreased repeat business, and ultimately, a dent in your brand’s reputation. Moreover, the cost implications of delays add up quickly through increased labor costs, expedited shipping fees, and potential loss of customers.

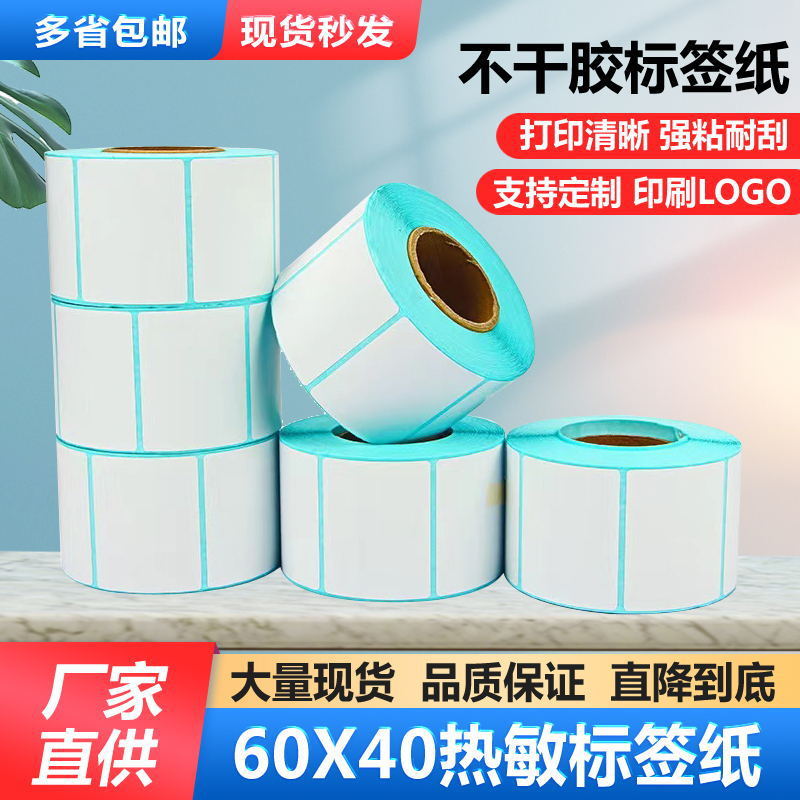

One pivotal role that often flies under the radar is labeling. Good labeling systems streamline operations by ensuring packages are accurately identified and routed correctly, reducing the risk of human error. Labels also provide crucial information for inventory management, package tracking, and compliance with shipping regulations.

Understanding the Different Types of Label Paper

The first step in choosing the ideal label paper for your dispatch operations is understanding the various types available. Thermal labels offer substantial advantages like fast printing speeds and minimal operational costs since they don't require ink. However, they fade quicker when exposed to light or heat, making them unsuitable for long-term storage.

Laser and inkjet labels are best used when superior print quality is required, such as with high-resolution logos or detailed graphics. They tend to be more durable than thermal labels but come with higher material and maintenance costs. Specialized labels fit unique needs; for example, moisture-resistant and temperature-resistant labels ensure durability in challenging environments.

Criteria for Choosing the Ideal Label Paper

Several criteria should guide your decision-making process when selecting label paper. Compatibility with your current printing technology is paramount—nothing stalls operations faster than mismatched equipment. Durability and adhesive strength determine the lifespan and reliability of the labels, especially vital for long-haul shipments and adverse weather conditions.

Readability and print quality are crucial for scanning and manual reading alike. Ensure that your labels remain legible throughout their journey from warehouse to end consumer. Lastly, consider the environmental factors like recyclability and sustainability. Eco-friendly options contribute positively to your corporate social responsibility initiatives.

Tailoring Label Paper to Specific Delivery Platforms

Selecting the right label paper also depends on the nature of your delivery platforms. For e-commerce businesses handling bulk shipping versus individual orders, easy-to-peel thermal labels might speed up processing times. Courier services prioritize speed and efficiency, so durable labels that withstand rough handling are essential.

Warehousing and inventory systems benefit from batch labeling solutions, which help maintain stock accuracy and facilitate quick reorders. In these settings, barcode paper or weighing paper can integrate seamlessly into automated systems for real-time updates and reporting.

Case Studies: Success Stories in Optimizing Dispatch with Ideal Label Paper

Consider an e-commerce giant who reduced shipping errors significantly after switching to high-quality thermal label paper. Their improved readability and durability meant fewer packages were returned due to faulty addresses. A local courier service adopted specialized moisture-resistant labels, resulting in a noticeable improvement in delivery times during rainy seasons.

A warehouse doubled its efficiency by incorporating sturdy, heavily adhesive labels for its heavy machinery parts. These labels remained intact despite the rough industrial environment, allowing for smoother inventory checks and streamlined workflow.

Common Pitfalls and How to Avoid Them

Business owners often overlook printer compatibility when choosing new label paper, leading to mechanical issues and production halts. Another common mistake is ignoring environmental conditions—the chosen labels may not stand up to humidity, extreme temperatures, or abrasion. Finally, underestimating the volume of labels needed can disrupt supply chains and delay shipments.

Expert Tips for Maintaining Label Quality

To sustain the quality of your label paper, store them under optimal conditions—cool, dry, and away from direct sunlight. Regular printer maintenance prevents jams and ensures clean prints. Train your staff on proper label application techniques; improper sticking methods can result in labels peeling off before reaching their destination.

Future Trends in Label Paper for Dispatch Operations

The future holds exciting advancements in smart labeling technology, including RFID tags that provide real-time data about the package's location and condition. Eco-friendly innovations continue to grow, offering biodegradable and recyclable label papers without compromising performance. Integration with automated dispatch systems will further enhance efficiency, minimizing human intervention and reducing errors.

Conclusion

In summary, investing time and resources in selecting the ideal label paper pays dividends in optimizing dispatch operations. From enhancing customer satisfaction to cutting operational costs, the benefits are numerous. Remember to account for printing compatibility, durability, readability, and environmental impact in your choices. High-quality label paper isn't just a consumable item; it's a strategic asset that drives efficiency and growth in your logistics chain.