The Importance of Product Tracking in Inventory Management

The realm of inventory management is vast and intricate. Efficient product tracking forms the cornerstone of this complex system, making it indispensable for businesses large and small among various industries.

Challenges of Inefficient Product Tracking

Ineffective product tracking often leads to significant operational disruptions. Imagine delays in locating items during peak demand periods or an inflated risk of discrepancies between recorded and actual inventory levels. These inefficiencies culminate in heightened operational costs and can erode trust with customers due to stockouts or incorrect deliveries.

The Role of Labeling in Product Tracking

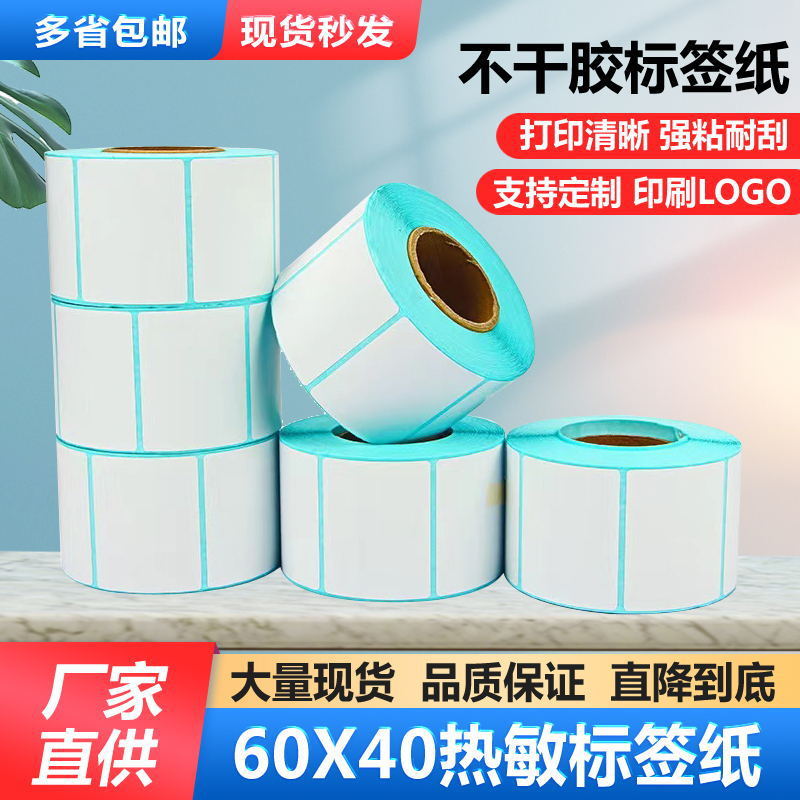

A critical enabler of efficient product tracking is proper labeling. Labels that are clear and readable at a glance ensure smooth scanning and instant recognition of products on shelves. However, common issues such as fading prints, illegible fonts, and poor adhesive quality can hinder their effectiveness.

Benefits of 60*40 Label Sizes

Optimal Size for Readability and Information

The utilization of 60*40 labels addresses many challenges associated with improper labeling. This size provides ample space for essential details including SKU numbers, barcodes, and concise product descriptions. Enhanced visibility ensures quick recognition and accurate scanning even from a distance, drastically improving workflow efficiency.

Compatibility and Versatility

Another key benefit of 60*40 labels is their versatility. They are suitable for a wide range of product dimensions and types, ensuring consistency across various categories. Furthermore, these labels easily integrate into existing labeling systems without requiring extensive modifications.

Implementing 60*40 Labels in Your Inventory System

Steps to Transition to 60*40 Labels

Transitioning to 60*40 labels begins with assessing your current labeling practices to identify areas needing improvement. A phased implementation approach is advisable, starting with testing within specific departments before company-wide application. This strategy minimizes disruption while maximizing adoption benefits.

Tools and Software for Effective Labeling

Investing in effective tools like barcode printers and scanners fortifies the transition process. Additionally, opting for inventory management software equipped with robust labeling capabilities streamlines operations and supports comprehensive tracking mechanisms.

Case Studies and Real-World Applications

Success Stories

Numerous companies have reaped substantial rewards by adopting 60*40 labels. Quantifiable improvements include increased tracking accuracy, reduced instances of misplaced items, and expedited order processing times. Such success stories highlight the tangible benefits and underscore the importance of using optimally sized labels.

Practical Examples

Industries such as retail, warehousing, logistics, and manufacturing demonstrate practical utility in real-world scenarios. Retailers leverage these labels to maintain organized shelves, warehouses rely on them for precise stock control, and manufacturers benefit from streamlined production flows.

Best Practices for Maintaining an Organized Product Tracking System

Regular Audits and Updates

For sustainable success, periodic inventory audits remain crucial. Regularly auditing your inventory ensures accuracy, identifies discrepancies early, and mitigates potential errors. Equally important is updating the labels as products evolve over time to account for changes in technology or organizational needs.

Employee Training and Compliance

Comprehensive training programs for employees emphasize the significance of accurate labeling. By fostering a culture of diligence and precision, organizations can maintain high compliance levels with established protocols, further enhancing overall inventory management.

Future Trends in Labeling and Product Tracking

Technological Advancements

The evolution of labeling technologies promises exciting advancements such as RFID tags and smart labels, facilitating real-time product tracking through the integration with IoT devices. These innovations present opportunities for even more refined tracking systems going forward.

Sustainability and Eco-Friendly Labels

There's also a growing emphasis on sustainability within the industry. The trend towards eco-friendly labeling materials demonstrates a commitment to environmental responsibility, reducing waste and energy consumption while maintaining labeling efficacy.

Summary of Key Takeaways

Enhanced Efficiency with 60*40 Labels

In closing, integrating 60*40 labels significantly enhances product tracking processes by offering optimal readability and flexibility. Such improvements not only streamline operational workflows but also bolster overall inventory management strategies.

Adopting Best Practices for Long-Term Success

Maintaining a robust product tracking system necessitates continuous improvement and adaptation. Leveraging cutting-edge technology ensures your organization remains agile, ready to meet future demands. Embrace best practices for sustained excellence in inventory management.