In the world of label printing, understanding thermal paper is essential. Thermal paper is a specialized paper that changes color when exposed to heat; it is widely used across various industries due to its efficiency and convenience. By examining its composition—typically involving a base layer coated with chemicals that react when heated—we see how an image or text forms without ink.

This type of paper finds applications in numerous fields including retail, logistics, healthcare, and banking. Examples include barcode labels, receipts, shipping labels, and medical charts. Given its pervasive use, mastering the art of storing and handling thermal paper efficiently is crucial.

The first key aspect is maintaining optimal storage conditions. Ideal temperature ranges are critical: store thermal paper between 20°C and 25°C (68°F to 77°F) for the best results. Equally important is humidity control; aim for a relative humidity level between 45% and 65%. Avoid direct sunlight and UV exposure as they can quickly degrade the paper's quality by causing premature fading.

Adequate ventilation is also necessary to prevent heat buildup, which could lead to unwanted reactions on the paper surface. Ensure there’s good airflow in the storage area but avoid excessive air dryness or dampness.

When it comes to loading thermal paper into printers, precision is paramount. Start by checking that your hands and tools are clean to prevent contamination-like smudges on the paper. Align the roll properly, ensuring no tears or wrinkles occur during installation—a common mistake is over-tightening the tension, causing jams and misfeeds.

Static electricity can be another enemy. To minimize static buildup, handle rolls carefully and consider using anti-static devices if you frequently face this issue.

Contaminants such as oils, solvents, and adhesives pose significant threats. Always keep thermal papers away from these substances and use protective covers and packaging whenever possible. Clean hands and tools are not just preferred; they’re vital for maintaining pristine paper conditions.

For long-term storage solutions, utilitarian containers resistant to environmental factors are recommended. Organize them well with clear labeling and cataloguing systems to enable quick retrieval when needed. Rotating stock periodically is advised to prevent aging—to maintain integrity, inspect stored thermal paper regularly for signs of deterioration.

Environmental considerations have become increasingly relevant. Opt for eco-friendly thermal paper alternatives to reduce overall impact. Proper disposal and recycling following manufacturer guidelines further mitigate negative effects. Remember, gestating environment impacts like pollution or extreme climate shifts can hasten degradation.

Troubleshooting degraded thermal paper involves recognizing signs like fading, discoloration, or loss of print quality early on. Quick fixes might include adjusting storage conditions or switching out compromised rolls. If problems persist, turn to the support provided by manufacturers who often offer warranties.

Technological advances continually improve thermal paper durability and sustainability. Innovations in coatings and substrates enhance resistance against contaminants and physical damage. Future trends may incorporate features facilitating superior longevity or ease integration with digital record-keeping systems.

Insights from industry professionals emphasize adhering strictly to best practices. Case studies demonstrate successful methods that anyone can emulate for better results. Recommended resources provide deeper knowledge and training opportunities for those looking to hone their expertise.

Investing in practical tools and accessories pays dividends. Use sturdy storage containers designed specifically for thermal paper, shelves offering proper support, and careful handling tools to prevent accidental damage. Employing protective wraps adds an extra layer of defense against harm.

An interactive Q&A section based on reader submissions proves invaluable. Addressing real-world concerns about thermal paper usage offers customized guidance and strategic insights directly applicable to specific scenarios.

Summarizing key points, implementing a checklist for storing and handling thermal paper ensures compliance with best practices. Proactive measures foster extended durability and performance excellence, leading companies toward prudent material management.

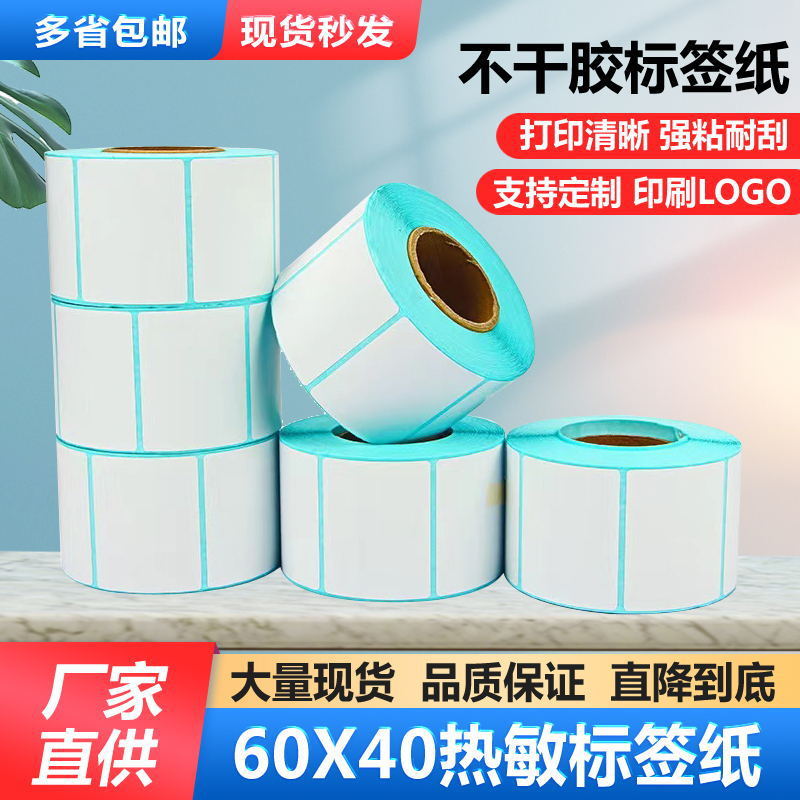

Product Information:

- Product Name: Label paper Thermal paper 60x40 barcode paper 60*40 weighing paper Printing paper Delivery platform label paper Weighing paper

- Manufacturer: Ding Tai Lace Limited Company

- Description: Ding Tai Lace Limited Company specializes in manufacturing high-quality printing materials. Our products include label paper, thermal paper, barcode paper, weighing paper, and delivery platform label paper. Experience seamless printing with our top-quality products. Your satisfaction is our priority.

- Price: $0.52 per unit

By integrating these best practices, businesses can optimize their thermal paper care processes effortlessly, securing lasting utility and operational efficiency. For any queries or detailed guidance, feel free to reach out through our contact platforms.